Warning: To use the services of our website you need to be enabled on your browser cookies.

|

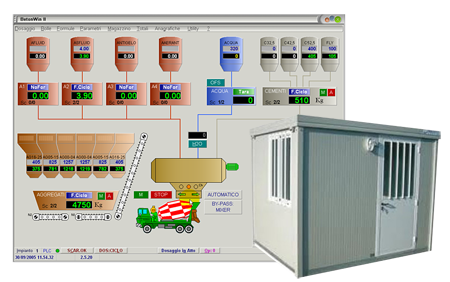

Betonwin2 |

Description

Together with control panels above mentioned, BETONWIN2 control system can be provided as well. It includes a group of accessories to manage the whole plant from one single workstation:

Cabin with door and window, dim. 1800x2400xh2500 mm ;

PC with Windows o.s., BETONWIN2 software to handle the plant, monitor 19", printer A4;

Panel with PLC;

Support shelf for all mobile panels and PLC case.

However, it is anytime possible to work around the BETONWIN2 control system and use mobile control panels to manage the plant, just by choosing this option on the proper selector device.

The user friendly interface simplifies daily tasks of the plant's operator, providing at the same time plenty of information. Each step of the cement mixer truck's loading schedule can be personalized by choosing the proportioning sequence of products and its synchrony with no restrictions. The "Load preset" function allows early preparation of scheduled loads, giving the operator a quick start capability as soon as machinery are available and ready, thus optimizing the plant output capacity.

The system features an advanced data and reporting interface, complete with delivery notes management, including layout set up and printout, practically with no configuration boundaries. Orders and deliveries control shows both output and progress carried on along the day.

All data generated are always updated in real time, and are available for reports and statistics. For easier control and processing, BETONWIN2 can be interfaced with any kind of accounting and invoicing software application.

Safety backups are created automatically by the program: all results and parameters are saved in a safe place, and can be accessed to restore the plant.

BETONWIN2 can also be used for remote assistance service, in order to allow a technician not physically located in front of the plant, to diagnose the system's functionality, or to restore a minor fault situation. A remote workstation can be connected via LAN to the main system, providing full control of the plant from any location, acting also as backup unit in case of failure of the main PC.

Nevertheless, it is anytime possible to use the software in simplified mode, this to allow unskilled users to carry on the production with no efforts.