Warning: To use the services of our website you need to be enabled on your browser cookies.

|

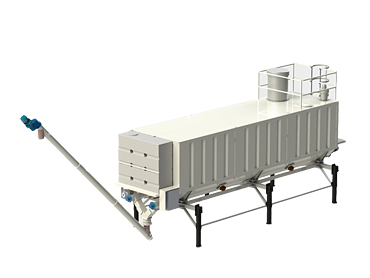

Model BTH |

HORIZONTAL SILO "BTH" is a movable plant with accurately designed features. It is used to store and to proportion cement or dust into the cement mixer truck or into the mixer. Unlike vertical silos, it has low environmental impact and does not require a base made of concrete to be fixed above. For this reason it can be located everywhere, and particular licenses are not required.

Easy to be carried, it is provided with hydraulic pistons and can be loaded and unloaded by means of transport without using a crane. All models can be bended to reduce the room they need: the screw pump can be placed in supports on sides of the silo, and the dust filter can be settled on proper bars.

The silo has got a loading pipe with a linking flange, it is used to load cement from the tank truck with a pressure of 1 bar. It is provided with deduction load cells, thus all quantities are proportioned deducting their weight from the total stored. Storage capacity available are 20, 30, 40 and 50 m3.

Concrete is extracted by the horizontal screw pump, it is later carried by the pulling inclined screw pump (provided with an adjustable spherical connection), and consequently ends to 4,2 m in height. Vibrators located inside the body of the silo can be turned on in case of emergency, else, they can help and fully empty the silo.

HORIZONTAL SILO "BTH" is created to get out exact amount of materials; moreover, it allows to check the quantity of concrete bought and left-overs.

Cement system is managed separately by one single control panel which can handle fresh water system as well.

The electronic terminal has got a keyboard and a display, and it allows to easily oversee automatic programs.

If HORIZONTAL SILO "BTH" is combined with AGGREGATES HOPPER "BT", the whole plant can be managed by one single PC station. For further details, please check the "Betonwin2 control system" paragraph.

All plants are varnished by professional companies: each product is exposed to a continuous cycle of sandblasting and high quality spray painting. This particular treatment grants long life to all of its components.

1

1